Summary

- We assist you in changing the ways that you can operate through integrated holistic visualization.

- The evaluation of visualization provides you with the capacity to maintain your competitive advantage permanently.

- First of all, it is possible to enhance efficiency and prevent expenditures.

- Then link digital threads up and downstream to suppliers and customers to outcompete rivals even more.

- Lastly, redesign your market with new business models and develop entry barriers to a greater extent.

Vr For Design

A co-creating design solution incorporates structured and unstructured data for detailed visualization of products, systems, and construction projects.

- Multifunctional crews don't waste time, from data collection to the implementation of the recommendations

- Both reviewers are using the same model with different interfaces located in other places or spaces

- Automated model building

- It is easy to modify and transform its elements

- Faster and better decisions

- Shorter time to market

- Reduced design cycles

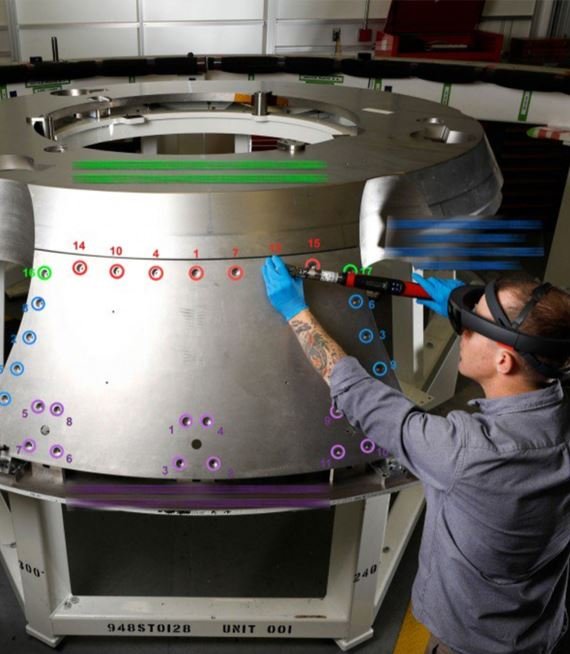

Vr For Manufacturing

Using technologies such as AV, the present layouts of manufacturing plants, how cells and tools are constructed, and real-time manufacturing data can be visualized. Train operators and digital environments in the form of twin models.

- Scanned, BIM, and CAD sources of data

- Real-time process and quality information as well as contextual data from MES, the quality, and contextual data feeder

- Designing and implementing plant and product digital twins

- A ramp-up of new manufacturing sites

- More efficient manufacturing processes

- Reduced waste

- Improved health and safety

Vr For Training

The following are some benefits of using 3D tutorials for a product: Offering a live environment to end-users like operators, customers, or maintenance engineers with the product and with the procedures of handling the product, if needed, one can incorporate annotations such as animations in the virtual environment.

- Early launch of new products into the market

- Quick creation and alterations of training without having to code

- Improved manufacturing efficiency

- Lowers the risk of costly mistakes in production

- Improved health and safety

- Decreased requirements for the time needed and the resources that have been expended on the training of engineers

- Less likely to be halted by production interruptions